It’s a case of tail wagging the dog

Traditional supply chain costs make up 5-10% of the Profit and Loss, where true operating costs (including materials) make up 60-70%, yet so many businesses talk about how they optimised their supply chain in isolation to the true operating costs; very few connect the two. Doing so can unlock so much more in delivering a business strategy.

End to End optimisation starts from Raw Material manufacturing and ends at the customer, by considering this in your operating model design the opportunity to realise significantly greater opportunities than just the supply chain emerges. But we must not forget that operations are the backbone of your entire business model and the key linkage to allow true end to end optimisation.

We see too many projects built from a supply chain (trucks and sheds) solution that either miss huge opportunities or lock the business out of delivering long-term strategy.

Start from perfect but recognise what is ‘good enough’ for now

So, you are through the first hurdle, and it’s time to turn up the heat on your new supply chain. What should you do?

- The word ‘chain’ is incredibly important, every element is connected and you cannot consider a section without considering the whole.

- Don’t be afraid to put costs in to take costs out that are greater; hence why it’s important to realise you are working with a chain.

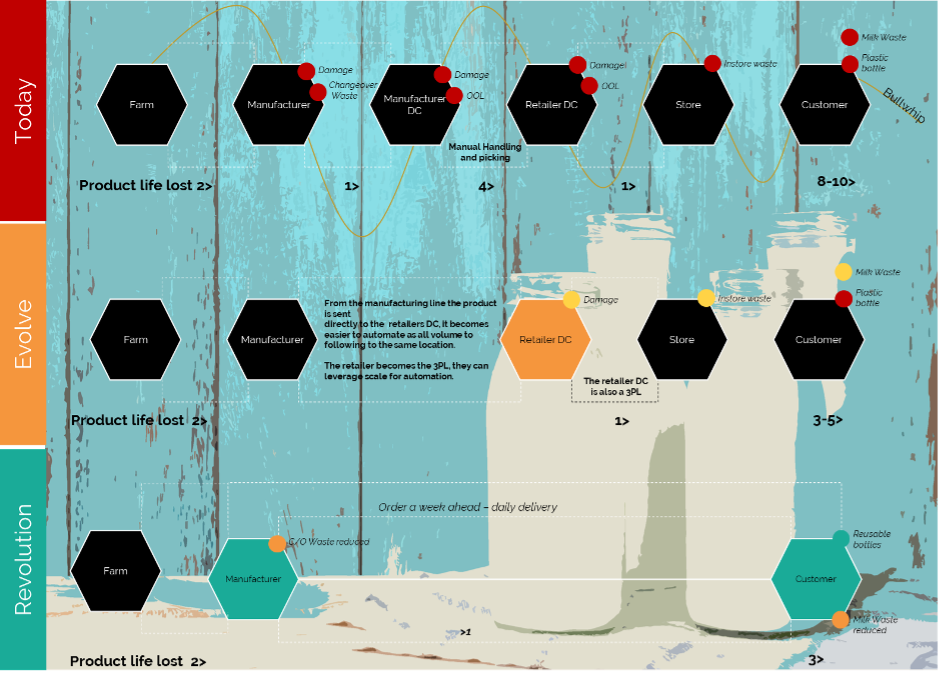

- Consider the costs of others; suppliers, customers etc. and how you could put costs into your business that reduce costs or vice versa. A great example is stock; the best place to hold stock is as close to the customer as economically possible. So often we see multiple stock locations which have buffer stocks just to ensure they replenish the next buffer. Consider the example of fresh milk (Figure 1).

- Start with perfect and work backwards. If you had a blank canvas and your volume tomorrow, what would you do? Once this is established, map the art of the possible in moving towards this.

- If there is a big move you can make in 2-3 years, allow your current model the flexibility to allow that to occur and do not take the last 1% for a 10-year deal.

Figure 1

The hypothesis and future state scenarios have been identified, what next?

Use science, brains and logic. What you change now will be the solution for the future so consider the implications and risks on the changing the world. Will your solutions be flexible to respond whilst being lean and a competitive advantage for tomorrow? Automation is the future, but is it your tomorrow?

If you are going to buy a fully automated solution, specification is critical. Under-spec it and you risk buying a “dud” from day one. Over-spec it and the business case might not stack up. Most importantly, you might have over-capitalised. Most businesses therefore play too safe and over-spend.

We have seen multi-million-dollar projects where the specification and design is based on a rudimental calculation to work out depth of racking and the number of robots based from safe averages. That business now has an automated warehouse that is running at about 60% utilisation yet has some products that will not work and are stored in a 3PL.

Be flexible in design. Consider blending solutions and most importantly, model the sh*t out of your design using real numbers and proper maths. Using a digital twin and simulating the real-world volume and constraints will give you confidence before you sink $40m when $25m would do.

Final thoughts – big trends to consider

Digital supply chains have really been driven by the B2C fulfilment, but these smarts can easily be applied to B2C. Creating visibility in data and information through the supply chain can identify bottlenecks, reduce inventory, and optimise freight and logistics and reduce warehouse costs. There are some businesses who think the solution to the current market is to hold more stock and are investing in more footprint: this is an excessive fixed cost. There are others that are smarter, and optimising using technology to review the supply chain outside of their own.

The final trend we see is Campus manufacturing, when manufacturing was offshored the trend became warehouses, some manufacturers jumped on this and disconnected manufacturing from warehousing even locally.

That will reverse, warehousing and manufacturing will be co-located, and this will grow with the onshoring of manufacturing. Nibble on-site high bays could start to drop at the back and front of manufacturing sites around the country – done right it’s a lower cost, more efficient, solution.

However, perhaps people are not thinking enough about their location choices, who is around them and how might this drive the long-term costs. A great example is fresh food, especially super fresh, take the dark kitchen concept for Deliveroo and apply it to large scale to factories.

Paul Eastwood; CEO – Pollen Consulting Group